Powder coating is a popular finishing method for industrial and commercial products. The process involves spraying a dry powder onto a metal substrate and then curing it in an oven to create a durable, long-lasting finish. However, the application process can be messy and inefficient if not done properly. That’s where powder coating booths come in. In this blog post, we’ll explore how powder coating booths save time and reduce waste in production.

How Do Powder Coating Booths Save Time?

One of the primary benefits of using a powder coating booth is that it can save time in the production process. Without a booth, workers would need to manually apply the powder coating to the substrate, which can be a messy and time-consuming process. With a booth, however, the application process is streamlined and more efficient.

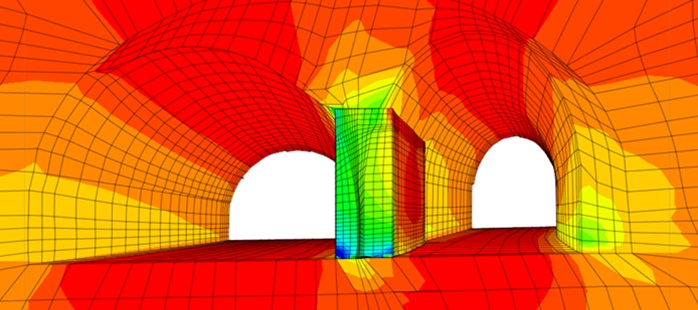

For example, powder coating booths are designed to ensure that the powder is applied evenly and uniformly to the substrate. This means that there is less overspray and waste, which can save time and reduce the need for rework.

Additionally, powder coating booths often feature automated systems for moving parts in and out of the booth. This can save time and reduce the risk of injury, as workers don’t need to manually handle heavy or awkward pieces of equipment.

How Do Powder Coating Booths Reduce Waste?

In addition to saving time, powder coating booths can also reduce waste in the production process. This is because the booths are designed to capture excess powder and prevent it from escaping into the air. The powder that is captured can then be reused, which can reduce material costs and waste.

Some powder coating booths even feature advanced filtration systems that can capture up to 99% of the overspray. This not only reduces waste but also improves air quality in the production facility.

The Benefits of Using Powder Coating Booths

Using powder coating booths has several benefits for production facilities. In addition to saving time and reducing waste, powder coating booths can also improve the quality and consistency of the finished product.

Powder coating booths ensure that the powder is applied evenly and uniformly, which can reduce the risk of defects and rework. The booths also provide a controlled environment for the powder coating process, which can improve the adhesion and durability of the finished product.

Furthermore, using a powder coating booth can help production facilities comply with environmental regulations. By capturing excess powder and preventing it from escaping into the air, powder coating booths can reduce air pollution and improve the overall sustainability of the production process.

Choosing the Right Powder Coating Booth

When it comes to choosing a powder coating booth, there are several factors to consider. The size of your production facility, the type of products you’re coating, and your budget are all important considerations.

You’ll also need to decide whether you want a batch or continuous feed system. Batch systems are best for small to medium-sized production runs, while continuous feed systems are better for larger volumes.

Additionally, you’ll need to consider the airflow and filtration system of the booth. Look for a booth that features a high-quality filtration system that can capture overspray and prevent it from escaping into the air.

Finally, consider the features of the booth itself. Does it have adequate lighting and ventilation? Is it easy to clean and maintain? These factors can all impact the efficiency and effectiveness of your powder coating process.

Conclusion

Powder coating booths are an essential tool for any production facility that uses powder coating as a finishing method. By streamlining the application process, reducing waste, and improving the quality and consistency of the finished product, powder coating booths can save time, reduce costs, and improve overall productivity. If you’re considering incorporating powder coating into your production process, be sure to invest in a high-quality powder coating booth to maximize your efficiency and minimize waste.